We provide high voltage cable harnesses and associated wiring solutions to our electric and hybrid vehicle customers in the automotive, mass transit and specialist vehicle sectors. We are at the forefront of this growing and exciting technology and we are proud to be associated with the global drive to lower CO2 emissions.

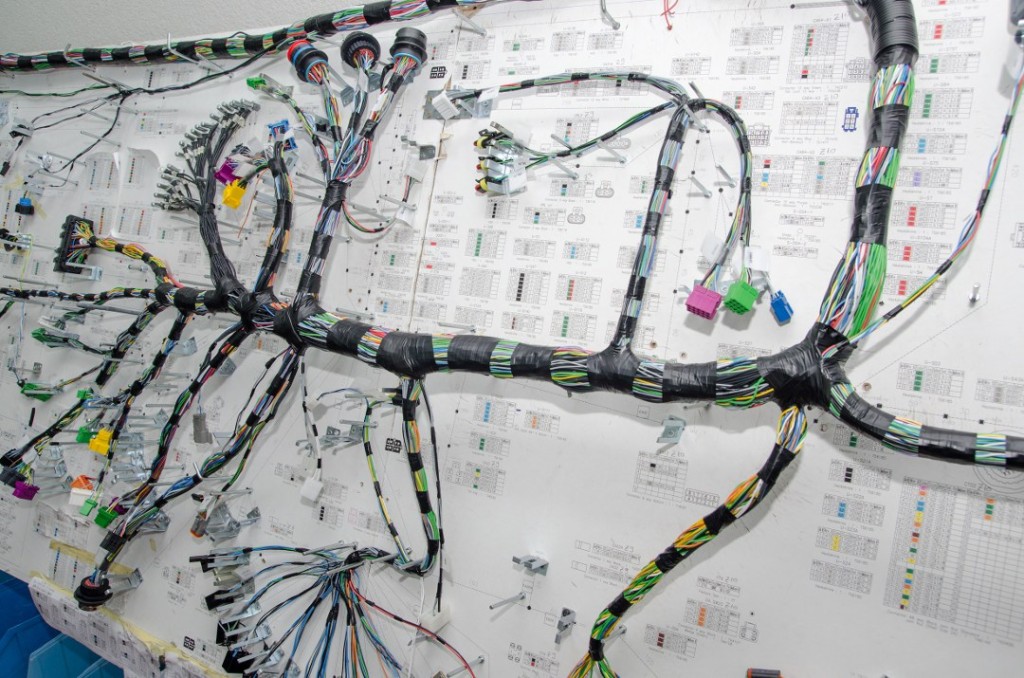

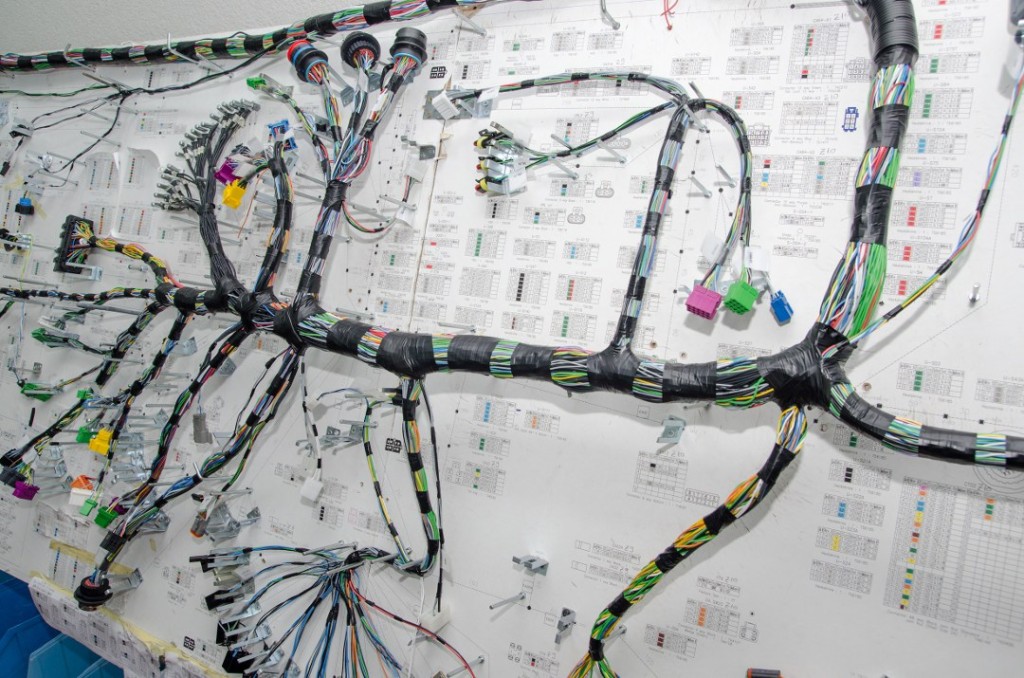

Excel Assemblies manufactures a variety of open bundle wire harnesses for safety critical, harsh and demanding applications.Our harnesses are produced to exacting specifications using robust and repeatable manufacturing methods and controls and in accordance with our TS16949 and ISO9001 Approvals.

Excel Assemblies manufactures a variety of open bundle wire harnesses for safety critical, harsh and demanding applications.Our harnesses are produced to exacting specifications using robust and repeatable manufacturing methods and controls and in accordance with our TS16949 and ISO9001 Approvals.

Excel Assemblies manufactures a variety of encapsulated harnesses, where complete environmental protection is required.

Excel Assemblies manufactures “closed bundle” harnesses for use in harsh and rugged environments. The use of convoluted & PVC tubing provides environmental protection and abrasion protection. Many of our products are IP rated to prevent water ingress. Additionally the addition of tubing can add to the aesthetic appeal of the assembled harnesses.

Excel Assemblies manufactures “closed bundle” harnesses for use in harsh and rugged environments. The use of convoluted & PVC tubing provides environmental protection and abrasion protection. Many of our products are IP rated to prevent water ingress. Additionally the addition of tubing can add to the aesthetic appeal of the assembled harnesses.

Excel Assemblies manufactures a variety of braided harnesses, where extra protection is required, be it high temperature or high wear resistance. Excel Assemblies operate braiding machinery ranging from 8 to 48 carriers, capable of braiding a variety of materials, including Nomex, Nylon / Engineered Yarns, PEEK and Stainless Steel.

Whether it is new build or repair and overhaul, Excel Assemblies has vast experience in box and panel assembly.We have a vast experience in bring together Electromechanical Sub Assemblies and Systems, Commercial Boxes (COTS) and Panel Assemblies

Whether it is new build or repair and overhaul, Excel Assemblies has vast experience in box and panel assembly.We have a vast experience in bring together Electromechanical Sub Assemblies and Systems, Commercial Boxes (COTS) and Panel Assemblies

Where product integrity is of paramount importance, Excel Assemblies uses Ultrasonic Welding which is an automated and controlled process to ensure robustness and reliability of the join. Ultrasonic welding has advantages over standard / traditional splicing and avoids unnecessary processes being applied to the cable joint and thus reducing time and cost

Excel Assemblies provides on-site support for anything from technical advice to harness / assembly repair and qualification. A dedicated team of professionals are on hand to take your queries and to deliver you solutions

Excel Assemblies provides on-site support for anything from technical advice to harness / assembly repair and qualification. A dedicated team of professionals are on hand to take your queries and to deliver you solutions